Auction Closed

Bayou Wasco Insulation, LLC

(2) Complete Insulation Systems to Produce Extruded and Injection Molded Subsea Pipe Insulation

Auction #210347

Description

Available For Immediate Sale This opportunity includes (2) Complete Insulation Systems to Produce Extruded and Injection Molded Subsea Pipe Insulation HT-100 GLASS SYNTACTIC POLYURETHANE (GSPU) Polyurethane (PU) based subsea wet insulation system filled with hollow glass microspheres (HGMS). HGMS is a 3M product made from silica glass in the form of 30 micron diameter spheres. HGMS improve resistance to heat…

Ended

Mon, Jul, 11th

10:00 AM

CST6CDT

Address

4611 Curtis Lane

New Iberia, LA

New Iberia, LA

Description

Available For Immediate Sale

This opportunity includes (2) Complete Insulation Systems to Produce Extruded and Injection Molded Subsea Pipe InsulationHT-100

GLASS SYNTACTIC POLYURETHANE (GSPU)

Polyurethane (PU) based subsea wet insulation system filled with hollow glass microspheres (HGMS). HGMS is a 3M product made from silica glass in the form of 30 micron diameter spheres. HGMS improve resistance to heat flow within the PU matrix and are resistant to extreme crushing forces found at subsea water depths. PU systems for subsea applications are formulated to resist chemical breakdown in hot and wet service conditions.

HT-150

5-LAYER POLYPROPYLENE (5LPP)

5-layer polypropylene (solid, foam and syntactic) flow assurance system for deepwater applications, most typically utilized for the thermal management of subsea flowlines. Insulation is designed to perform at high-service temperatures and is an alternative to GSPU.

Dates

Bidding Dates

Monday

4

Apr '22

4

Apr '22

at

12:00 AM

CST6CDT

12:00 AM

CST6CDT

Monday

11

Jul '22

11

Jul '22

at

10:00 AM

CST6CDT

10:00 AM

CST6CDT

Preview Dates

Pre-bidding Dates

Checkout Dates

Marketing

BAYOU WASCO

Flow Assurance Products

HT-100

GLASS SYNTACTIC POLYURETHANE (GSPU)

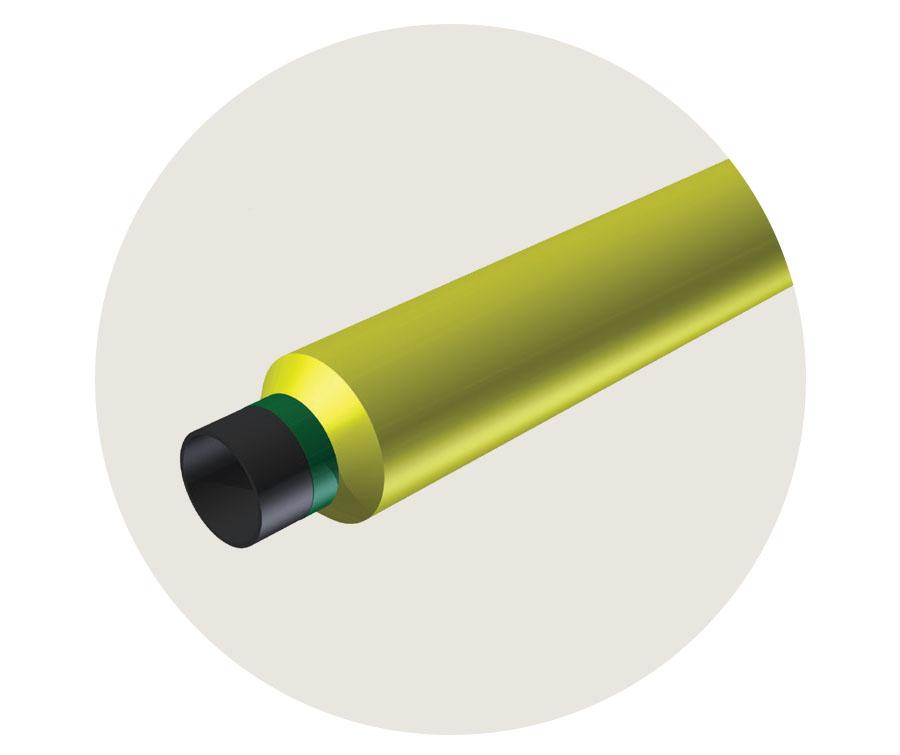

• Polyurethane (PU) based subsea wet insulation system filled with hollow glass microspheres (HGMS) • HGMS is a 3M product made from silica glass in the form of 30 micron diameter spheres. HGMS improve resistance to heat flow within the PU matrix and are resistant to extreme crushing forces found at subsea water depths • PU systems for subsea applications are formulated to resist chemical breakdown in hot and wet service conditions. Bayou Wasco uses Dow HYPERLAST™, as well as other products. • GSPU is a reaction injection molding (RIM) product. PU components and HGMS are blended and injected into steel molds that surround the pipe’s outer surface • GSPU delivers excellent thermal insulation, adhesion, impact strength and durability across a broad spectrum of demanding installation and operating conditions • GSPU facility boasts an industry-leading molding process, significantly reducing the risk of costly quality issues during installation and field joint operations

GLASS SYNTACTIC POLYURETHANE (GSPU)

• Polyurethane (PU) based subsea wet insulation system filled with hollow glass microspheres (HGMS) • HGMS is a 3M product made from silica glass in the form of 30 micron diameter spheres. HGMS improve resistance to heat flow within the PU matrix and are resistant to extreme crushing forces found at subsea water depths • PU systems for subsea applications are formulated to resist chemical breakdown in hot and wet service conditions. Bayou Wasco uses Dow HYPERLAST™, as well as other products. • GSPU is a reaction injection molding (RIM) product. PU components and HGMS are blended and injected into steel molds that surround the pipe’s outer surface • GSPU delivers excellent thermal insulation, adhesion, impact strength and durability across a broad spectrum of demanding installation and operating conditions • GSPU facility boasts an industry-leading molding process, significantly reducing the risk of costly quality issues during installation and field joint operations

Primary Specifications • 3 in. min to 24 in. max OD • Pipe lengths: 35 ft. min to 42 ft. max • Thermal conductivity: 0.1-0.17 W/mK • U-Value Range: 1.5 W/m2K and higher • Min operating temp: -35°C • Max operating temp: 115°C • Water Depth Range: 0-3,000 m

HT-150

5-LAYER POLYPROPYLENE (5LPP)

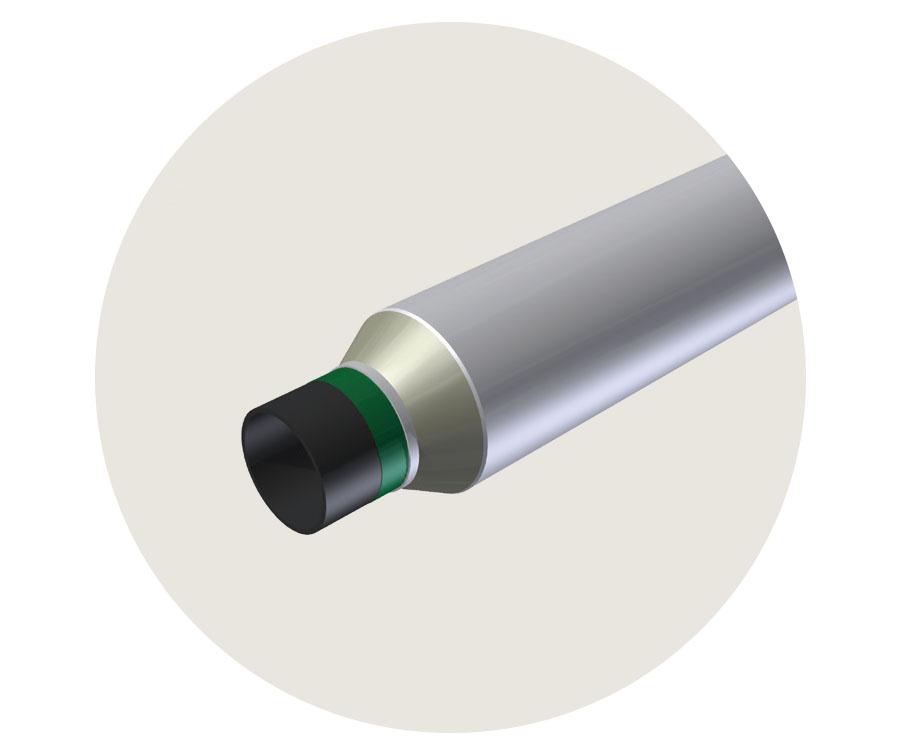

• 5-layer polypropylene (solid, foam and syntactic) flow assurance system for deepwater applications, most typically utilized for the thermal management of subsea flowlines • Insulation is designed to perform at high-service temperatures and is an alternative to GSPU • Products are applied by a side extrusion process and various layers are employed to achieve the desired thermal and buoyancy requirements in accordance with project specs • Insulation work is performed in automated facility with minimal touch points between man, machine and material • 5-layer facility produces a high-quality output via its unmatched Pipe extruder paired with extra-long inlets and outlets to allow for a smoother flow of pipe through the facility with significantly tighter tolerance capabilities • Exclusive facility design allows for pipe to enter and remain in the facility until all coating runs are complete, negating the chance of minerals or other contaminants adhering to the pipe between runs

5-LAYER POLYPROPYLENE (5LPP)

• 5-layer polypropylene (solid, foam and syntactic) flow assurance system for deepwater applications, most typically utilized for the thermal management of subsea flowlines • Insulation is designed to perform at high-service temperatures and is an alternative to GSPU • Products are applied by a side extrusion process and various layers are employed to achieve the desired thermal and buoyancy requirements in accordance with project specs • Insulation work is performed in automated facility with minimal touch points between man, machine and material • 5-layer facility produces a high-quality output via its unmatched Pipe extruder paired with extra-long inlets and outlets to allow for a smoother flow of pipe through the facility with significantly tighter tolerance capabilities • Exclusive facility design allows for pipe to enter and remain in the facility until all coating runs are complete, negating the chance of minerals or other contaminants adhering to the pipe between runs

Primary Specifications • 6 in. min to 24 in. max OD • Pipe lengths: 35 ft. min 80 ft. max • Thermal conductivity: 0.1-0.17 W/mK • U-value range 1.5 W/m2K and higher • Min operating temp: -35°C to -20°C • Max operating temp: 150°C • Water Depth Range: 0-3,000 m

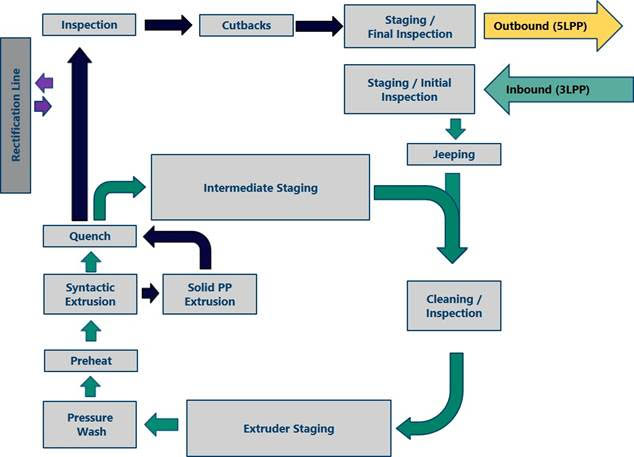

Process Flow

Directions

Location: 4611 Curtis Lane, New Iberia, LA 70560

Preview

By Appointment Only. Contact: Bob Saunders | 708-765-4026 | bob@integra-as.com

Terms

- A buyer`s premium of 16% will be added to the hammer price of each lot sold.

- Payment terms TBD. Acceptable forms of payment include wire transfer, cashier’s check, company check with bank letter of guarantee, or credit card (up to a maximum of $2000 - a convenience fee may be charged for credit card payments.)

- Invoices will include all applicable sales, export, use and other taxes due to any federal, state or local taxing authority, shall be in addition to the sale price and shall be paid to Integra at the time of sale of the Purchased Assets. Detailed tax and exemption information will be provided. To receive the benefit of any tax exemption, buyer must supply Integra Asset Solutions with a properly completed sales tax exemption certificate, for acceptance and approval prior to any invoice adjustment of said taxes.

- For any buyers residing outside the United States or Canada, a wire transfer deposit will be required for approval to participate in the sale. Any deposits made will either be applied to the buyer’s invoice or refunded within 5 business days if a purchase is not made.

NO GUARANTEES OR WARRANTIES WHATSOEVER EITHER EXPRESSED OR IMPLIED.

PURCHASERS ARE STRONGLY ENCOURAGED TO INSPECT THE ITEMS BEFORE BIDDING.

FAILURE TO MAKE PAYMENT OR REMOVE ANY/ALL PURCHASED ASSETS WITHIN SPECIFIED TIMELINE, MAY RESULT IN CHARGED COSTS TO BUYER FOR ANY LOSSES INCURRED TO RESELL ASSETS, INTEREST, LEGAL FEES, MOVING, STORAGE, AND COMMISSIONS.

ALL SALES ARE FINAL - NO EXCEPTIONS

For complete removal and sale terms, reference the Complete Terms and Conditions.

Removal

- Removal days: TBD

- Buyer shall be responsible for the safe and proper removal of any items purchased by the buyer. Integra does not pack, ship, store, crate, or rig items. Buyers may either pick up items at the designated auction site personally or can contract a third party to manage the removal process for them. Before items can be removed by a designated third party, buyer must provide Integra with (1) paid-in-full invoice and (2) "Buyer Release Form” which allows Integra to release items to a third party contractor for shipping, crating, rigging or packing purposes. Any person, buyer or rigger, performing removal will need to provide proper insurance.

- All hand-carry items must be removed within 48 hours of the conclusion of the sale. Integra shall have no responsibility whatsoever for any missing or lost items if items were not removed during the aforementioned timeframe. There will be NO removal of any items until the auction is complete.

- After the buyer has removed any item from Integra’s possession, Integra shall have no obligation to make any adjustment or accommodation to buyer because of any mistake in quantity or other defect or problem with respect to such item. Buyer must make all requests for adjustments in writing to Integra before any item is removed from the premises where the auction is conducted.

- Any items, including all associated parts, components, and accessories, if applicable, not removed on or before the published removal date, may at the option of Integra, be subject to a fee of $500 per day. Furthermore, any items not removed on or before the removal date shall be deemed abandoned and Integra shall have no further obligation to the buyer with respect to such items.

- Pre-qualified riggers will be posted here when they become available. Integra is not affiliated with any machinery rigging, transport, or export company. Rigging information is provided solely as a courtesy to our buyers. Integra does not endorse or guarantee the services of any machinery rigging, transport, or export company, and cannot be held responsible for any damage or other problems incurred as a result of the actions of said companies.

Pre-Approved Rigger: TBD