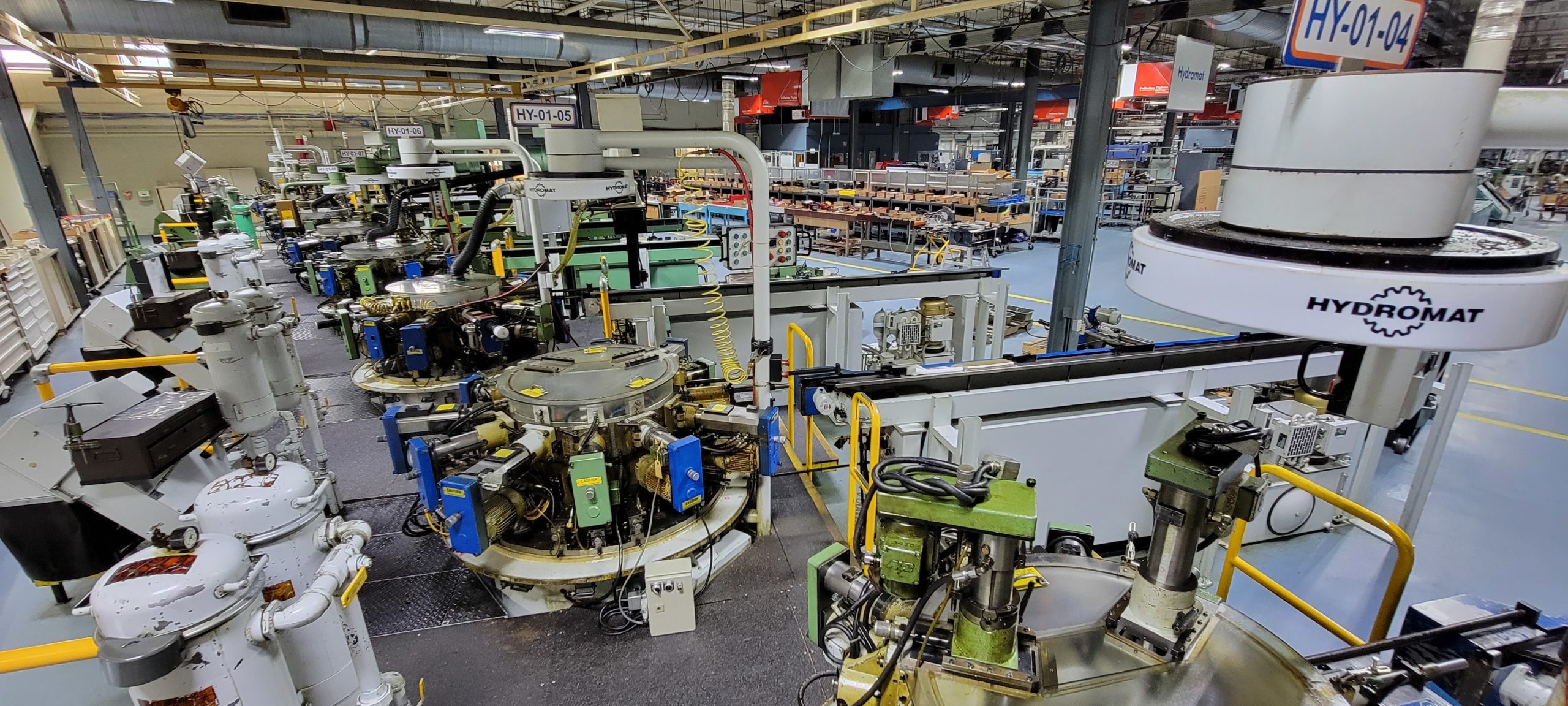

5-Day Auction Event of Assets from TE Connectivity – Company Winding Down Production and Relocating Select Assets to Other Facilities

- Large metal machining facility with over 150 machines and thousands of lots of support equipment sold during a 5-day auction event where setup and removal of the assets was executed while the client continued to wind down production

- Hazmat team was hired by company to decontaminate the plating department and all affected assets

- Removal process was performed on a strict schedule due to building’s logistical limitations

Days

Execution

After identifying operational redundancies, TE Connectivity, a global manufacturer of precision machined electronic components, made the strategic decision to close their 220,000 sq. ft. facility in Norwood, Massachusetts. The company engaged Integra to help facilitate the sale and removal of their assets. Throughout the entire four-month liquidation process, TE needed to travel down two parallel paths: completion of outstanding purchase orders and an organized wind down of overall operations, which included a robust inter-company asset transfer program. In addition, contamination was not only a concern, but also a reality that needed to be dealt with during our presence on site. The plating department had been contaminated, and TE Connectivity needed to hire a third-party hazmat company to decontaminate the affected areas and the items that would be sold at auction.

Nonetheless, our diligent setup team was able to organize, stage, photograph, write up, and catalog 2600 lots that were sold during a 5-day auction event. With the help of an effective marketing strategy, the sale generated nearly 1000 registered auction participants from 19 different countries, 25% of whom were successful bidders.

Further, the client’s landlord had set an aggressive timeline for them to exit the building. Setup and removal logistics during this project were challenging due to the building’s segmented layout. The coordination of equipment removal post auction had to be executed with a hyper-organized and stringent “by appointment only” schedule, as the lack of loading docks proved to be a serious logistical impediment. This extended the total removal time to 8 weeks and a total project execution time of 120 days.